🔥 Fuel Combustion Efficiency: The Science of Maximizing Energy and Reducing Waste

Introduction

Fuel combustion efficiency plays a crucial role in how effectively energy is converted from fuel into useful work. Whether it’s powering a car engine, an industrial furnace, or a household generator, efficient combustion determines not only the performance and cost-effectiveness of the system but also its environmental impact. In today’s energy-conscious world, improving combustion efficiency is essential for reducing fuel consumption, cutting carbon emissions, and achieving sustainable energy goals.

What Is Fuel Combustion Efficiency?

Fuel combustion efficiency is the measure of how completely a fuel is burned and how much of its chemical energy is converted into heat or mechanical energy.

In simple terms, it reflects how well a system uses fuel without wasting energy in the form of unburned hydrocarbons, heat loss, or incomplete combustion.

The ideal combustion process, often called stoichiometric combustion, is when the exact amount of air required for complete burning is supplied to the fuel.

However, in real-world conditions, achieving 100% efficiency is nearly impossible due to:

- Heat loss through exhaust gases

- Imperfect air-fuel mixing

- Mechanical limitations of engines or furnaces

The Science Behind Combustion

Combustion is a chemical reaction between fuel and oxygen that releases energy in the form of heat and light.

The process can be expressed as:

Fuel (Hydrocarbon) + Oxygen → Carbon Dioxide + Water + Energy

Example:

CH₄ + 2O₂ → CO₂ + 2H₂O + Heat

When there’s not enough oxygen, incomplete combustion occurs, producing carbon monoxide (CO), soot, or unburned hydrocarbons, leading to lower efficiency and higher pollution.

Key Factors Affecting Combustion Efficiency

- Air-to-Fuel Ratio (A/F Ratio)

- The right proportion of air to fuel is critical.

- Too much air (lean mixture) leads to energy loss; too little air (rich mixture) causes incomplete combustion.

- Fuel Quality

- Fuels with higher octane or cetane numbers burn more efficiently and cleanly.

- Impurities like sulfur reduce combustion quality.

- Temperature and Pressure

- Higher combustion temperatures improve reaction rates but may increase NOx emissions.

- Optimal pressure ensures complete burning in engines.

- Mixing and Atomization

- Fine mixing of air and fuel enhances combustion uniformity.

- Poor atomization (especially in diesel engines) leads to inefficiency.

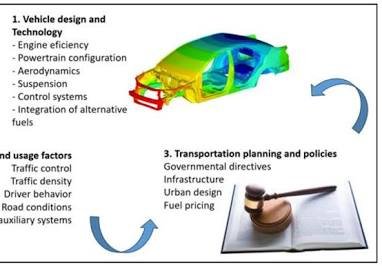

- Engine or Burner Design

- Advanced technologies like turbocharging, direct injection, and swirl combustion chambers boost efficiency.

- Maintenance and Calibration

- Dirty filters, clogged injectors, or misaligned spark plugs reduce combustion performance.

Measuring Combustion Efficiency

Efficiency can be measured by analyzing:

- Oxygen (O₂) levels in exhaust gases

- Carbon dioxide (CO₂) concentration (higher = better combustion)

- Carbon monoxide (CO) and unburned hydrocarbons (HC) (lower = better efficiency)

- Flue gas temperature (lower exhaust temperature = less heat loss)

Modern combustion analyzers use sensors to calculate real-time efficiency and adjust systems for optimal performance.

Technologies That Improve Combustion Efficiency

- Electronic Fuel Injection (EFI): Ensures precise fuel-air mixing for engines.

- Turbochargers and Superchargers: Improve air intake, enhancing burning quality.

- Catalytic Converters: Reduce harmful emissions while maintaining efficiency.

- Exhaust Gas Recirculation (EGR): Lowers combustion temperature and NOx emissions.

- Combustion Optimization Software: Used in power plants and industries to monitor and control combustion in real-time.

Benefits of High Combustion Efficiency

- Reduced Fuel Consumption: Saves money and conserves resources.

- Lower Emissions: Decreases carbon monoxide, hydrocarbons, and nitrogen oxides.

- Improved Engine Life: Cleaner burning prevents carbon buildup.

- Enhanced Performance: Delivers more power per unit of fuel.

- Environmental Protection: Supports global sustainability efforts.

Challenges in Achieving Maximum Efficiency

Despite technological advancements, complete combustion remains difficult due to:

- Variations in fuel composition

- Changes in temperature and load conditions

- Mechanical wear in engines

- Balancing efficiency with emission regulations

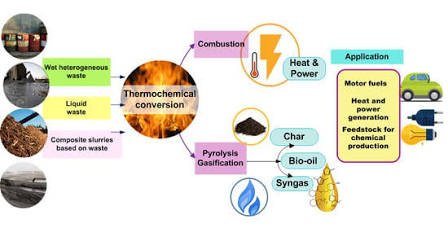

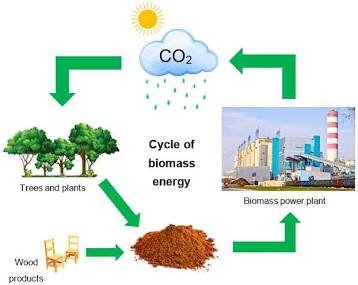

Therefore, modern research focuses on adaptive control systems, alternative fuels (like hydrogen or bioethanol), and advanced sensors to maintain peak performance.

Future of Fuel Combustion Efficiency

The future lies in smart, AI-controlled combustion systems that automatically optimize air-fuel ratios, pressure, and ignition timing in real time.

Additionally, blending synthetic fuels, hydrogen, and biofuels with traditional fuels can lead to cleaner and more efficient combustion.

In the coming years, hybrid and dual-fuel engines may dominate, offering a perfect balance between efficiency, power, and environmental responsibility.

Conclusion

Fuel combustion efficiency is more than a technical metric—it’s a cornerstone of modern energy sustainability. By maximizing the energy extracted from every drop of fuel, industries and consumers can achieve lower costs, cleaner air, and a more sustainable future.

Whether in vehicles, factories, or power plants, enhancing combustion efficiency remains a key goal in the global transition toward cleaner and smarter energy systems.

Post Comment